What Techniques Are Used In TIG Welding A Root Pass?

Many jobs, like nuclear work, piping and consumer goods, require at least the root pass, or the first weld in the pipe joint, to be done with the process of TIG welding, or tungsten inert gas welding. Root passes use weld filler material to close the root space between the weld faces, and are particularly useful when only one side of the weld is accessible. Follow tips regarding shielding gas, welding preparation and weld techniques make TIG welding your root pass successful.

Back-Purging Techniques

Purge the weld zone with argon at about 40 cubic feet per hour. Without adequate shielding, welding defects like incomplete penetration, root pass cracking, root pass suck-back and lack of fusion can occur. There are two common methods for back purging a pipe root pass weld zone: purging the whole volume of a long pipe run or locally purging the immediate volume around the weld zone. A ratio of about 4:1 between the back flow purge rate and the welding torch flow rate is needed to make a sound root pass weld.

Welding Preparation

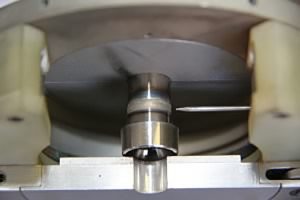

Preparation of the pipe ends is very important in root pass welding. Clean the pipes to bright, shiny metal for a distance of about 1 inch form the weld preparation edge, then thoroughly clean and degrease the whole area. Also, you need to get the proper fit of the pipes that you are welding. The root gap should be at least 1/32 inches larger than the diameter of filler wire being used to weld. This will allow for the manipulation of filler wire even if some closure occurs during welding.

Tack Welding

Tack welding is necessary to ensure that the pipes do not move during closure welding. Make sufficiently large tack welds and put them often enough around the diameter of the joint so that the filler is smaller in diameter than the root gap. Grinding the tack welds to a feather edge may be helpful. It may prevent small defects that can be detected during radiographic examination from occurring when you make the closure weld.

Closure Welding

When closure welding, keep the joint sealed except in areas being welded. Maintain gas purge pressure for the first two passes to ensure that the root pass will not be tremendously oxidized during subsequent weld passes. Move your torch in a continuous motion from sidewall to sidewall, adding filler wire where the joint as not been tack-welded. Position the filler metal in the root gap opening. This will reduce the possibility of the root gap closing up, limiting weld reinforcement at the root.

While you can very well do all of these techniques and tricks on your own, it would be better that you hire a certified welding company to do the job for you, especially if you have little experience with TIG welding as well as root pass welding. This way, you are assured that you are getting the best possible TIG welding service and products, all for your own convenience and safety.

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

You MUST Ask BEFORE Hiring a Welding Company – So You Can Avoid Wasting Your Time AND Hard-Earned Dollars”

Keep in Touch